Deep drawing steel dds deep drawing steel dds is typically produced as low carbon steel with a max carbon of 0 06 c interstitial free i f steel is also allowed at producer s discretion but is not required.

Extra deep drawing steel properties.

The drawing and forming steels must be differentiated from the supraform hr and tm ranges which are.

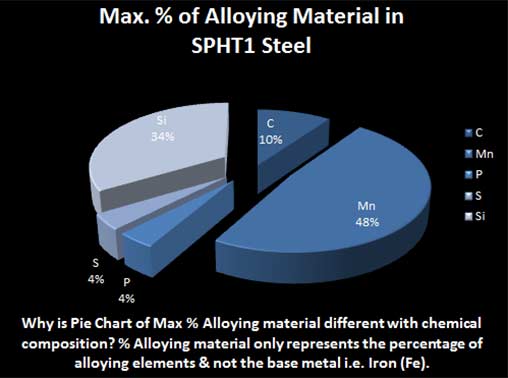

Edds is composed of maximum 0 002 percent of carbon maximum 0 4 percent manganese maximum 0 02 percent phosphorous maximum 0 02 percent sulphur.

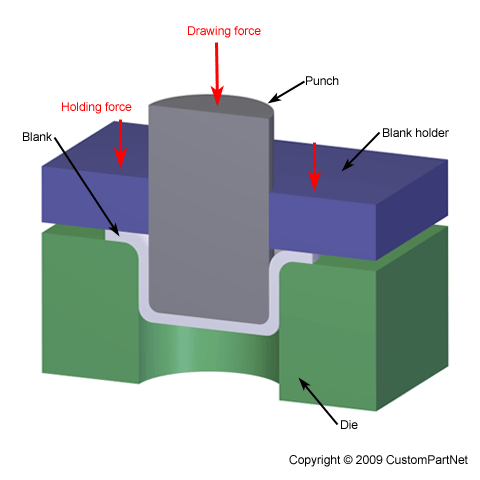

It is thus a shape transformation process with material retention.

Dd13 hr2 extra deep drawing properties for applications involving severe drawing.

Also called edds or eddq it is a type of steel that typically contains less than 0 005 percent carbon and uses a low level of titanium and or columbium to tie up hardening elements to create an interstitial free chemistry that produces an extremely refined grain pattern.

Dd11 hr4 drawing or forming quality for general forming applications.

This type of steel should be ordered for applications that require the most consistent type of low carbon steel.

Deep drawing is a sheet metal forming process in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch.

For deep drawing steel must have good formability which means the steel has the ability of plastic deformation without fracture and loss of stability.

Extra deep drawing steel edds this material is intended for fabricating identified parts where extremely severe drawing or forming in excess of the abilities of ds and dds materials may be involved or when a product essentially free of aging is required.

Dd12 hr3 deep drawing quality for general drawing applications.

The process is considered deep drawing when the depth of the drawn part exceeds its diameter.

During the process of deep drawing a high level of rejection takes place in case the design of die is not proper or if the steel does not have the properties needed for deep drawing.

Deep drawing steel dds deep drawing steel dds is typically produced as low carbon steel with a max carbon of 0 06 c interstitial free i f steel is also allowed at producer s discretion but is not required.

This type of steel should be ordered for applications that require the most consistent type of low carbon steel.

Edds steel is for extra drawing sure stabilized steel whereas dds type c is for deep drawing only.

Remaining is iron with other impurities.